How to change hydraulic gear pump rotation

How to Change the Rotation of a Hydraulic Gear Pump: A Step-by-Step Guide

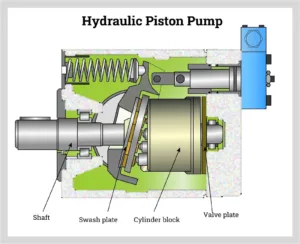

Hydraulic gear pumps are widely used in various industrial applications, such as machinery, automotive systems, and heavy equipment, to circulate hydraulic fluid and provide power to different components. In some instances, it may be necessary to change the rotation direction of a hydraulic gear pump to suit a specific application or adjust the system’s operation. This guide will help you understand how to change the rotation direction of a hydraulic gear pump, along with important considerations and safety precautions.

Understanding Hydraulic Gear Pump Rotation

Hydraulic gear pumps have a fixed direction of rotation, typically either clockwise (CW) or counterclockwise (CCW), depending on the pump design. The direction of rotation determines the flow of hydraulic fluid through the system and can affect the efficiency and performance of the system. If you need to change the rotation direction, it’s crucial to understand the pump type and the mechanics involved.

Method for Changing the Rotation of a Hydraulic Gear Pump

There are several ways to alter the rotation of a hydraulic gear pump, depending on the pump type, model, and design. Below is a detailed, step-by-step method to change the rotation direction of a hydraulic gear pump:

1. Determine the Pump’s Design

- Fixed Rotation Gear Pumps: Many hydraulic gear pumps are designed to operate in a specific direction. If your pump has a fixed rotation, you may need to disassemble and reassemble the pump components.

- Reversible Gear Pumps: Some hydraulic gear pumps are designed to allow the rotation to be reversed. If this is the case, refer to the manufacturer’s manual for specific instructions.

2. Disconnect the Power Source

- Before performing any work, ensure that the pump is not connected to any power source (electrical or mechanical). Disconnect any hydraulic lines or power transmission components such as motors, drives, or belts to avoid injury or damage to the system.

3. Identify the Pump’s Mounting Configuration

- The rotation direction may be influenced by how the pump is mounted to the system. In some cases, reversing the mounting configuration may change the direction of rotation.

- Clockwise (CW) Rotation: If the pump is currently rotating clockwise and you wish to change it, check if you can reverse the mounting position or make adjustments to the pump’s drive shaft.

- Counterclockwise (CCW) Rotation: Similarly, if the pump is rotating counterclockwise, adjustments may be needed to modify the mounting.

4. Reassemble the Pump Components (If Applicable)

- For fixed rotation gear pumps, you may need to disassemble the pump and reposition the gears to change the rotation direction. This may require adjusting the gear assembly or switching parts within the pump casing. Ensure you follow manufacturer guidelines when performing these tasks.

- For reversible pumps, simply follow the manufacturer’s instructions to reverse the flow direction. This may involve rotating the pump casing or changing the direction of the input shaft.

5. Check the Hydraulic System Configuration

- After reversing the pump, check your hydraulic system for any changes in pressure, flow rates, and connections. Ensure that all seals are intact and that the system remains free of leaks.

6. Test the Pump

- Once the rotation has been changed, carefully test the pump by running the system under low-pressure conditions. Observe the flow of hydraulic fluid, and ensure the pump is operating as expected.

- Perform a system check to verify that the hydraulic circuit is functioning correctly and there are no issues related to fluid circulation or pressure.

Important Considerations and Safety Tips

- Consult the Manufacturer’s Manual: Before attempting any modifications to the pump, always refer to the manufacturer’s manual for detailed specifications and instructions.

- Compatibility: Ensure the pump and hydraulic system components are compatible with the new rotation direction.

- O-Rings and Seals: Changing the rotation direction may require adjustments to O-rings and seals to ensure the system operates correctly and without leaks.

- Pressure Relief: Make sure the system is not under pressure when working on the pump to prevent injury.

- Professional Help: If you’re not familiar with hydraulic systems, it may be best to consult a professional technician to ensure the job is done safely and correctly.

Conclusion

Changing the rotation of a hydraulic gear pump can be necessary for optimizing system performance or ensuring compatibility with other equipment. By following the above steps carefully and paying attention to safety protocols, you can successfully alter the pump’s rotation direction. Always remember to consult your pump’s manual and seek professional advice if needed to avoid damaging the equipment or the system.

By implementing these steps, you can effectively maintain and optimize your hydraulic system to function at its best.