Hydraulic clutch explained: Diagram, Function, and Easy Bleeding Guide

Hydraulic Clutch Explained: Diagram, Function, and Easy Bleeding Guide

A hydraulic clutch is an essential component in modern vehicles, offering smoother and more efficient control over the gear shifting process. If you’ve ever wondered how a hydraulic clutch works, how to understand its diagram, or how to bleed it effectively, this guide is here to provide all the answers.

What is a Hydraulic Clutch?

A hydraulic clutch is a type of clutch system that uses hydraulic fluid to transmit the force required to disengage the engine from the transmission, allowing smooth gear shifts. Unlike the traditional mechanical clutch, which uses cables or rods to link the clutch pedal to the clutch mechanism, the hydraulic clutch relies on hydraulic fluid and a set of cylinders to perform the same task. This results in a more consistent pedal feel and improved reliability.

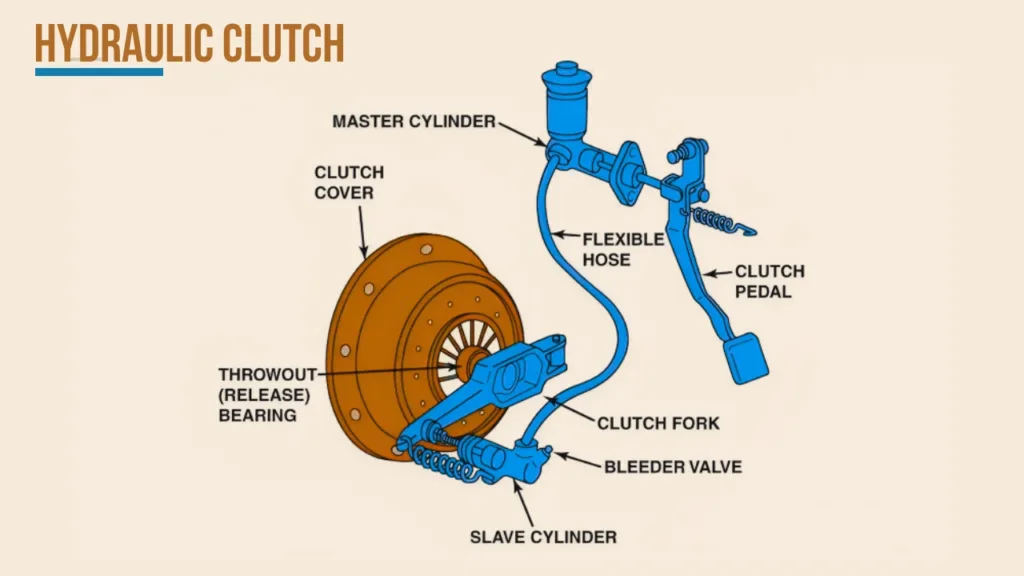

Key Components of a Hydraulic Clutch:

- Clutch Master Cylinder: This part is connected to the clutch pedal. When the pedal is pressed, it pushes hydraulic fluid into the system.

- Clutch Slave Cylinder: Located near the clutch itself, this component receives the hydraulic fluid from the master cylinder and uses it to disengage the clutch.

- Hydraulic Fluid: The fluid (often brake fluid or a special clutch fluid) is used to transfer the force from the master cylinder to the slave cylinder.

- Hydraulic Lines: These are the pipes or hoses that carry the hydraulic fluid from one cylinder to another.

Hydraulic Clutch Diagram:

Here’s a simple breakdown of how a hydraulic clutch works:

- Clutch Pedal: When you press the clutch pedal, it activates the master cylinder.

- Master Cylinder: The master cylinder then pushes hydraulic fluid through the lines to the slave cylinder.

- Slave Cylinder: The slave cylinder then uses the fluid pressure to push a rod, disengaging the clutch and allowing you to shift gears.

- Clutch: Once the clutch is disengaged, you can shift gears smoothly. Releasing the pedal allows the clutch to re-engage.

How Does a Hydraulic Clutch Work?

- Pressing the Pedal: When you push the clutch pedal, it moves a piston inside the master cylinder. This piston forces hydraulic fluid (usually brake fluid) through a hose to the slave cylinder.

- Slave Cylinder Action: The hydraulic fluid enters the slave cylinder and pushes a piston or push rod. This movement disengages the clutch, separating the engine from the transmission.

- Gear Shifting: With the clutch disengaged, the driver can shift gears without causing damage to the gearbox.

- Releasing the Pedal: When you release the clutch pedal, the master cylinder allows the hydraulic pressure to return to the system, causing the slave cylinder piston to retract, re-engaging the clutch and allowing the car to move again.

This process provides a smoother and more precise clutch operation, making it a preferred system in many modern vehicles, especially sports cars, motorcycles, and trucks.

How to Bleed a Hydraulic Clutch:

Bleeding a hydraulic clutch is essential when there’s air trapped inside the hydraulic lines, which can cause issues such as a soft or unresponsive clutch pedal. Air in the system can prevent proper fluid pressure from being applied to the slave cylinder, making the clutch hard to disengage or difficult to shift gears.

Here’s a step-by-step guide to help you bleed your hydraulic clutch effectively:

Tools Needed:

- Wrench or socket set (to remove bleeder screw)

- Clear plastic tubing

- A container to catch the fluid

- Brake fluid (or the specific clutch fluid recommended by your manufacturer)

- Assistant (optional but recommended)

Step-by-Step Bleeding Process:

- Check Fluid Levels:

- Start by checking the hydraulic fluid reservoir. If the fluid is low, top it up with the recommended fluid. Make sure it’s full before you begin bleeding.

- Locate the Bleeder Screw:

- The bleeder screw is located on the slave cylinder. It’s usually a small valve with a nut-like design. You might need to remove a protective boot or cover to access it.

- Attach the Tubing:

- Place one end of the clear plastic tubing over the bleeder screw and direct the other end into a container. This will catch the old fluid as it’s expelled.

- Prepare for Bleeding:

- If you have an assistant, have them sit in the vehicle and press the clutch pedal. Alternatively, you can use a clutch pedal pump (if you’re working alone).

- Loosen the Bleeder Screw:

- Slowly loosen the bleeder screw while your assistant presses the clutch pedal. You should see old hydraulic fluid and air bubbles escaping through the tubing.

- Pump the Pedal:

- Have your assistant pump the clutch pedal several times while you tighten the bleeder screw and release it again to let the air and old fluid out. Repeat this process until you no longer see air bubbles in the fluid, and the fluid appears clear.

- Check Fluid Level:

- After you’ve successfully bled the system, check the fluid level in the master cylinder and top it off if needed.

- Test the Clutch:

- With the bleeder screw tightened, test the clutch pedal by pressing it. It should feel firm and responsive, and the gear shifts should be smooth.

Signs You Need to Bleed Your Hydraulic Clutch:

- Soft or Spongy Pedal: If the clutch pedal feels soft or spongy, it’s usually due to air in the hydraulic system.

- Difficulty Shifting Gears: A hydraulic clutch should allow smooth gear shifts. If you have trouble shifting, especially when the engine is running, air in the system may be the culprit.

- Clutch Pedal Sticking: If the pedal sticks or doesn’t return to its normal position, it could indicate low fluid or trapped air.

Conclusion:

A hydraulic clutch is an advanced system that enhances the driving experience by providing smoother gear shifts and requiring less effort to disengage the clutch. Understanding its diagram, function, and knowing how to bleed it when necessary will keep your clutch in top condition and your vehicle running smoothly. Regular maintenance, including bleeding the clutch when needed, ensures longevity and proper operation of the system, helping you avoid unexpected issues.

If you’re unsure or uncomfortable with performing the bleeding process on your own, always consult a professional mechanic.